Editors Note: This is part of a series of informational articles by Daniel Halvorson on the causes of different types of artifacts in 3D Printed objects. You can see more of his articles here.

Infill Show-Through

Sometimes, infill is visible through the surfaces of a print. Even when the plastic is opaque enough not to show the infill by translucence, the infill pattern can sometimes be seen in the form of a slight structure or texture that it imparts to the outside of a print. This can occur two separate ways: for the top and the sides of a print.

Top Surface: “Pillowing”

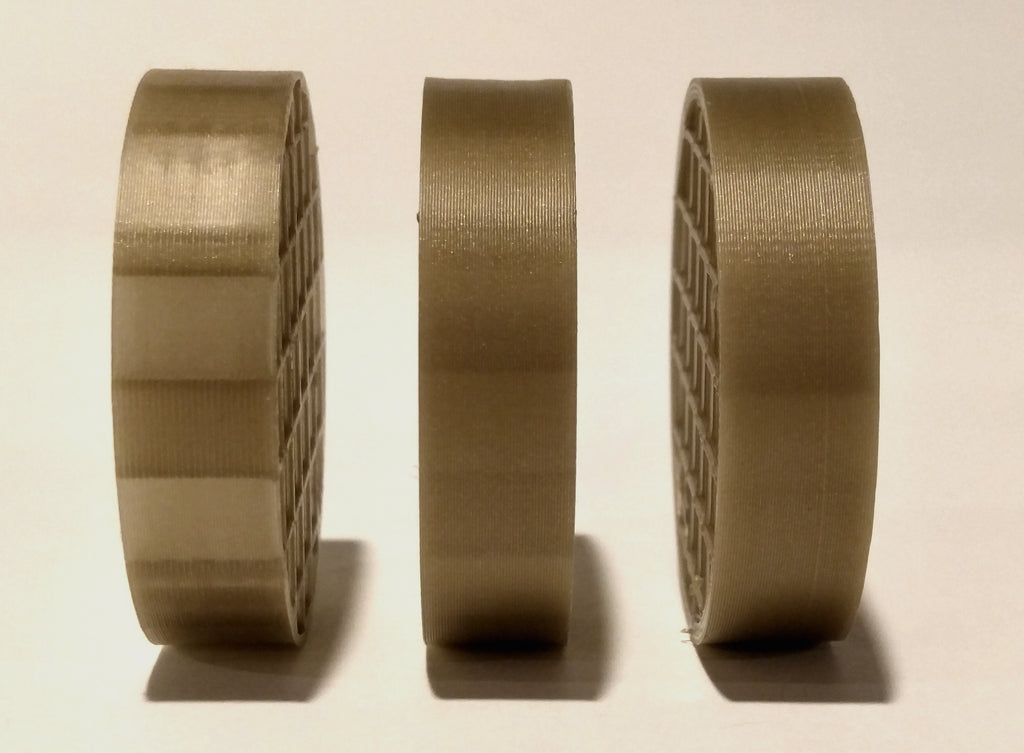

Wide, flat top surfaces can sometimes show a bubbled image of the infill. These sample disks were printed with a 0.1mm layer height, and all but the last one were printed with three top layers of solid infill.

The first (left) has a raspy texture and was printed fast and cool with no layer cooling. The second (right) was printed fast and hot, also with no layer cooling. Its pillowing is just as visible, but it is considerably smoother. The hotter nozzle temperature served to increase bonding between adjacent layers and traces.

This third test disk was printed slow and hot with the layer cooling fan set to maximum. This completely flattened the pillowing to the point where the top surface feels smooth to the touch. However, the pattern of the hexagonal infill beneath shows through the surface as a difference of sheen and color. This effect is finally removed in the fourth test print, which was printed with identical settings to the third test print except that ten solid layers of infill were used instead of three. With every additional layer of top solid infill the effect becomes less and less visible, as the next layer of plastic serves to add opacity as well as to smooth any texture that may have transferred up from the last layer.

Pillowing is a quirk caused by the interplay between a bridging behavior and a layer adhesion behavior. In short, the better bridging quality a printer is tuned to have, the better the first few layers of pillowing will be; the better the layer adhesion (which can depend on material choice, speed, and temperature), the faster the pillowing will disappear with each added solid layer of infill.

Sometimes when trying to tune a printer specifically for bridging quality versus tuning it for interlayer adhesion, certain settings can reach very different values. For instance, a high nozzle temperature typically increases adhesion but decreases bridging quality; also, some materials may be better suited toward one or the other. To reduce pillowing, it’s generally best to stick with middle-of-the-road values for these shared variables and instead focus on the variables that improve both bridging and adhesion, or at least the variables that improve one without significantly harming the other. These include slow printing speeds and a higher number of layers of solid top infill, as well as increased airflow for layer cooling.

Side Surfaces:

Textured stripes can occur where infill lines contact the sides of a print. The visibility of these lines will depend mostly on three slicer settings: the number of perimeters, whether the infill prints before the perimeters or vice versa, and the commanded overlap between the two. The first two will be briefly explained here, and the third will be dealt with in-depth in the article Advanced Infill Practices.

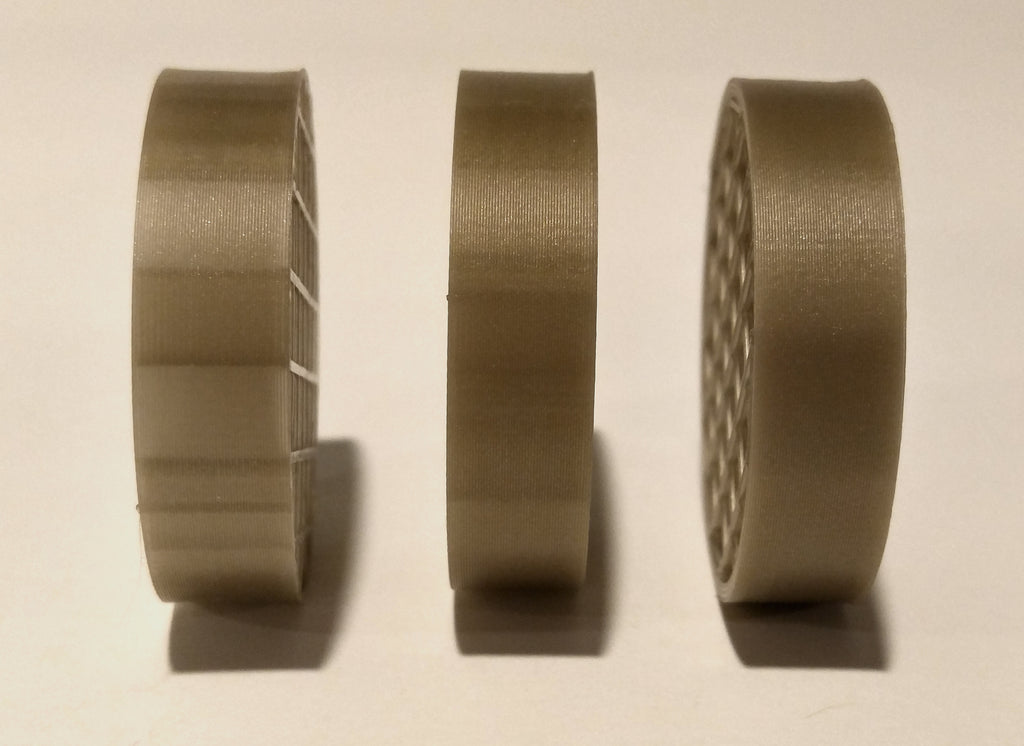

Going from left to right, these two sets of disks have one, two, and three perimeters. The first set is printed with each layer’s infill before the perimeters, and the second set is printed with the perimeters before the infill.

The general trend is clearly that more perimeter lines transmit less deflection from the infill lines to the exterior surface of the print. Also notice the visible improvement from the top three prints (where each layer’s infill was laid down before the perimeters) to the bottom three prints (where the perimeters came first). This improvement stems from the fact that the lines laid down first on each layer will push sideways on the next lines that contact them, but the first lines will not be significantly deflected by the new lines.

All sample models were printed with ColorFabb Pale Gold PLA/PHA, which is only slightly translucent. (This is useful for visibly demonstrating the effects of these settings.)

PRUSA RESEARCH ACQUIRES PRINTED SOLID INC. TO BE THEIR EXCLUSIVE RESELLER AND SERVICE CENTER IN THE USA

PRUSA RESEARCH ACQUIRES PRINTED SOLID INC. TO BE THEIR EXCLUSIVE RESELLER AND SERVICE CENTER IN THE USA